The 4 stroke engine process is the foundation of modern internal combustion technology. Whether you're building a racing go-kart, maintaining a lawnmower, or tuning a small motorcycle, understanding how the four strokes work will help you get the most performance, efficiency, and reliability out of your machine. This article walks you through each stroke in detail, explores how they work together, and explains why 4-cycle engines are ideal for certain applications.

Introduction to 4-Cycle Engines

What Is a 4-Cycle Engine?

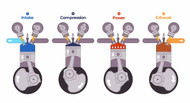

A 4-cycle engine, also known as a 4-stroke engine, completes its combustion cycle in four distinct strokes of the piston—intake, compression, power, and exhaust. These strokes convert fuel into mechanical energy through a controlled internal combustion cycle, allowing the engine to power various machines with precision and efficiency.

Where 4-Cycle Engines Are Commonly Used

4-cycle engines are widely used across several industries due to their durability and fuel economy.

Go-Karts

Performance go-karts frequently use 4-cycle engines because of their balance between torque and efficiency, especially when modified for racing.

Lawn Equipment

Lawnmowers, trimmers, and tillers often rely on 4-cycle engines for consistent power and cleaner emissions.

Small Motorcycles and Power Equipment

Scooters, ATVs, generators, and pressure washers commonly feature 4-stroke engines for their low maintenance needs and dependable power output.

The Four Strokes Explained

Understanding the individual roles of each stroke gives you insight into how fuel becomes power in small engine mechanics.

1. Intake Stroke

The first step in the cycle begins with the downward movement of the piston, drawing in a fresh mixture of air and fuel.

Role of the Intake Valve and Air-Fuel Mixture

As the piston descends, the intake stroke opens the intake valve, allowing the air-fuel mixture to enter the combustion chamber. The efficiency of this step directly affects how much power the engine can produce.

2. Compression Stroke

Next, the piston rises, compressing the air-fuel mixture into a tight space, which prepares it for combustion.

Piston Movement and Cylinder Pressure

During the compression stroke, both valves remain closed. The piston moves upward, significantly increasing the pressure and temperature of the mixture. A well-tuned compression phase boosts power and fuel efficiency.

3. Power Stroke

The third stroke is where energy is generated and transferred to mechanical motion.

Ignition, Combustion, and Energy Transfer

At the top of the compression stroke, a spark plug ignites the highly compressed mixture. This explosion forces the piston downward in the power stroke, driving the crankshaft and producing useful mechanical work.

4. Exhaust Stroke

The final stroke expels the byproducts of combustion from the cylinder, preparing the engine for the next cycle.

Removing Burned Gases Through the Exhaust Valve

As the piston rises again, the exhaust valve opens. The exhaust stroke pushes the spent gases out through the exhaust port, making room for a new intake charge.

How the Four Strokes Work Together

Each stroke plays a role in completing one combustion cycle. When combined, they form a seamless and efficient system.

One Complete Combustion Cycle = Two Crankshaft Rotations

A single cycle in a 4-stroke engine requires two full rotations of the crankshaft. This distinction is important when comparing timing, firing intervals, and mechanical output.

Timing and Valve Synchronization

Precision is key. Camshafts, crankshafts, and valves must be perfectly timed to maintain synchronization. Advanced small engine mechanics often involve adjusting this timing to improve engine behavior under specific conditions.

4-Cycle vs 2-Cycle Engines: What’s the Difference?

Understanding the difference between 4 cycle vs 2 cycle engines can help you decide which is better for your project or application.

Performance, Efficiency, and Maintenance Comparisons

4-cycle engines are generally more fuel-efficient and produce fewer emissions. They also run cooler and quieter than 2-cycle engines. However, 2-cycle engines are lighter and more powerful for their size, making them ideal for handheld tools and lightweight machines.

Why 4-Cycle Engines Are Ideal for Racing Mods

In go-kart and minibike racing, 4-cycle engines allow for more detailed customization. They can be modified for torque, speed, and throttle response with precision, giving racers better control and reliability on the track.

Why Understanding the Four Strokes Matters for Performance Builders

If you're modifying engines for racing or performance, understanding each stroke allows for smarter tuning and more reliable results.

Camshaft Timing and Stroke Phases

The camshaft controls the timing of the intake and exhaust valves. Adjusting cam profiles and timing can optimize each stroke for improved breathing, compression, and exhaust scavenging.

Tuning for Better Compression and Combustion

Altering compression ratios can make the compression stroke more aggressive, boosting power. However, it requires matching fuel quality and ignition timing to avoid engine knock.

Modifying Engines with ARC Racing Performance Parts

Using ARC Racing components can improve how your engine performs in each stroke. Billet flywheels, connecting rods, and performance cams are engineered for strength and reliability under racing conditions.

Common FAQs About 4-Cycle Engine Strokes

How many strokes does it take to start a 4-cycle engine?

A 4-cycle engine needs to complete a full cycle (all four strokes) before it starts running consistently. Depending on the engine’s state and the starter system, this may take a few crankshaft revolutions.

Can a 4-stroke engine fire every revolution?

No. A 4-stroke engine fires once every two revolutions of the crankshaft. This is because the power stroke only occurs after a full cycle of intake and compression.

How do I know if my engine is 2-stroke or 4-stroke?

Check for the presence of a separate oil reservoir (common in 4-stroke engines). Also, 4-stroke engines typically have a larger size, quieter operation, and a visible camshaft or valve cover.

What performance mods affect the stroke cycle?

Modifications like high-lift camshafts, high-compression pistons, and tuned exhaust systems directly affect how efficiently the intake stroke, compression stroke, and exhaust stroke perform—often improving torque, speed, or fuel efficiency.

Enhance Your 4-Cycle Engine with ARC Racing Upgrades

Whether you're building a kart, lawnmower racer, or minibike, ARC Racing offers the tools and expertise to unlock your engine’s full potential.

High-Performance Components for Each Stage of the Cycle

From improved valve springs for the intake stroke to forged pistons for better compression stroke durability, every part plays a role in cycle performance.

Billet Flywheels, Rods, and Cams Designed for Precision Timing

Our billet aluminum flywheels and rods are lightweight yet strong, allowing higher RPMs with reduced risk of failure. Cams designed for custom valve timing offer control over stroke overlap and duration.

Explore Our Engine Builder Kits and Tuning Support

For builders looking to push their engines further, ARC Racing offers complete kits tailored to various models. Each kit includes compatible components designed to improve the 4 stroke engine process while maintaining reliability and balance.

Maximizing Your Engine Performance: Final Thoughts

Understanding the four strokes of a 4-cycle engine gives you more control over performance, longevity, and modification potential. By learning how each stroke contributes to the internal combustion cycle, you can build, tune, or troubleshoot engines with more confidence. Whether you're racing, mowing, or customizing your next machine, ARC Racing has the precision parts and expertise to help you go further.